Experts agree that in color reproduction black can be beautiful if used wisely. Black can add details and contrast in the reproduction which is impossible to achieve with the three process colors. However, if the black is not used judiciously, it will do more harm than good. It will make the colors look dirty and create an unnatural contrast.

— Dr. R. K. Molla

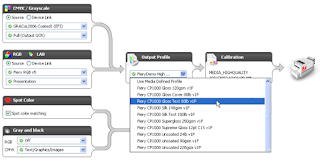

Reseparating customer supplied files is rapidly gaing popularity with printers and publishers as a way to lower print manufacturing costs. Reseperating allows for greater control of the final output, including specific filtering for media, color management, and finishing options.

Although the application is not limited to specific print market segments - these are the ones that are most quickly adopting this technology:

• Newspaper publishers

• Insert and flyer printers

• Magazine publishers

• Catalogers

• Directory printers

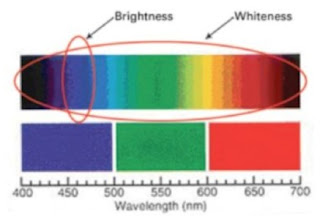

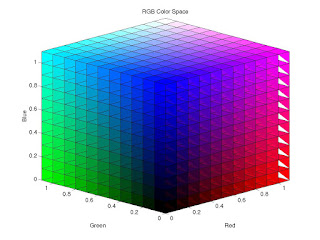

Within the CMY color space, a range of colors can be achieved by combining the three primaries. This combination in its turn can be thought of as a hue component (which will require a maximum of two primary colors) and a grey component (a mixture of all three, in an appropriate quantity to give the required saturation). If the grey component is replaced by black ink, the same color is being achieved by using two primaries and black. The act of substituting a quantity of black for the grey component is known as "Grey Component Replacement" (GCR).

GCR is also termed "achromatic color removal."

In grey component replacement (GCR), contrary to under color removal (UCR), the CMY values that add to grey all along the tone scale can be replaced with black ink. UCR only adds black to the CMY equivalent of what would have printed as a grey or near-grey.

Although there are many benefits to reseparating customer supplied files in order to use GCR, the most promoted and fairly easy to justify is in regards to reduced ink usage - typically suggested as a savings of around 20% in CMY inks with an increase of about 6% in K ink used while maintaining the same visual appearance in presswork.

Based on that figure, calculating a return on investment seems fairly straight forward. For example - based on the industry average of ink consumption for a sheetfed printer being about 2% of their gross earnings, a $10 million dollar a year printer will spend $200,000 a year on ink. If they reduce their ink usage by 20% they will save about $40,000 a year in ink costs. Theoretically, if the printshop spent $10,000 on a reseparation solution their payback time would be just three months and they will have saved $30,000 in the first year of implementation - a very good investment.

Based on that figure, calculating a return on investment seems fairly straight forward. For example - based on the industry average of ink consumption for a sheetfed printer being about 2% of their gross earnings, a $10 million dollar a year printer will spend $200,000 a year on ink. If they reduce their ink usage by 20% they will save about $40,000 a year in ink costs. Theoretically, if the printshop spent $10,000 on a reseparation solution their payback time would be just three months and they will have saved $30,000 in the first year of implementation - a very good investment.This is the removal of the gray components of the three colors and replacing them with black.

In GCR reproduction, all the primary and secondary colors remain the same as the normal chromatic reproduction, however, the blackening effects by the tertiary colors along with the gray components of the other two colors are removed and replaced with black.

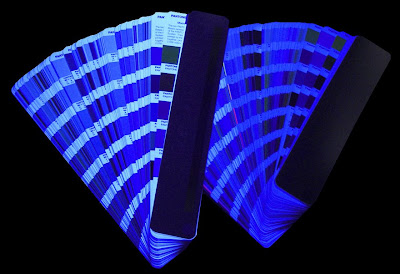

Various percentages of GCR can be applied to the separation for economical reasons and visually more pleasing results. The black dot sizes are increased to replace the gray component that has been reduced in the process colors. If 100 percent GCR were used, every color area in the reproduction might contain dots of only black and two or three process color inks.

Commonly used percentages are 50% to 75% GCR. The goal of GCR is more consistent color, increased detail in the shadows, shorter press makeready, and possible ink savings.

Advantage: GCR results in less ink being used, and some of that ink is black which is normally cheaper than the others.

Advantage: The areas where less ink is used are regions of high ink use, so the potential for drying and offset problems is reduced.

Advantage: The resulting output is less susceptible to changes in the printing variables since you are not continually trying to balance as much C, M, and Y.

Because a GCR separation uses a non-chromatic color – black – throughout the tonal range and reduces the proportion of C, M, and Y in the mid- and quarter tones, the color in GCR separated images is more stable as solid C, M, and Y ink densities naturally vary through a press run. Note, however, that the added stability means less ability for the press operator to move color if required. For many printers, the increased color stability is a perfect compliment to the industry trend for a “by the numbers” print manufacturing process.

Other advantages:

• Reduced make-ready times/faster start-ups/less wastage

• Harmonized separations enhance press form printability

• Reduced fan-out or web growth

• Dramatic improvement of image appearance when slight press misregistration occurs

• Reduced drying times

• Higher printing speeds

• Improved repeatability of print jobs

• Grey balance within images is more stable

Disadvantages of GCR include:

Advantage: GCR results in less ink being used, and some of that ink is black which is normally cheaper than the others.

Advantage: The areas where less ink is used are regions of high ink use, so the potential for drying and offset problems is reduced.

Advantage: The resulting output is less susceptible to changes in the printing variables since you are not continually trying to balance as much C, M, and Y.

Because a GCR separation uses a non-chromatic color – black – throughout the tonal range and reduces the proportion of C, M, and Y in the mid- and quarter tones, the color in GCR separated images is more stable as solid C, M, and Y ink densities naturally vary through a press run. Note, however, that the added stability means less ability for the press operator to move color if required. For many printers, the increased color stability is a perfect compliment to the industry trend for a “by the numbers” print manufacturing process.

Other advantages:

• Reduced make-ready times/faster start-ups/less wastage

• Harmonized separations enhance press form printability

• Reduced fan-out or web growth

• Dramatic improvement of image appearance when slight press misregistration occurs

• Reduced drying times

• Higher printing speeds

• Improved repeatability of print jobs

• Grey balance within images is more stable

Disadvantages of GCR include:

GCR may reduce the ability to adjust some colors.

--------------

Do you have a color management question, horror story or event to share?

Email me at reilley4color@gmail.com

Do you have a color management question, horror story or event to share?

Email me at reilley4color@gmail.com